FIELD SERVICES

At Nest Power, we identify problems before they become failures.

We specialize in both preventive and predictive maintenance, using advanced diagnostic technologies to monitor equipment health and plan interventions before breakdowns occur. We bring hands-on experience across diverse industries and operating conditions, ensuring you're not reacting to failure but staying ahead of it.

Our engineers are trained to detect early signs of Mechanical or Electrical Issues:

Looseness

structural or component-level

Resonance

leading to amplification of vibration

Lubrication issues

contamination, degradation, insufficient lubrication

Bearing degradation

such as spalling, fluting, or lubrication starvation.

Rotor rubs

contact between rotating and stationary parts.

Electrical faults

insulation breakdown, stator/rotor issues

Cavitation

in pumps due to vapor bubbles.

Flow turbulence or hydraulic instability

Thermal anomalies

hot spots in bearings, windings, or power electronicst.

Unbalanced power loads

indicating electrical or process problems.

Alignment drift

especially post-maintenance or thermal growth.

High vibration amplitudes at specific frequencies

hinting at particular fault types (e.g., gear mesh, blade pass)

Whether you need a one-time diagnostic or a long-term monitoring solution

we’re ready to help protect your assets and ensure continuous, efficient operation.

Machinery Diagnostic

- Vibration Analysis

- In-situ Balancing – Static & Couple

- Ultrasound Analysis

- Acoustic Emissions

- Infrared Thermography

- Rotor Dynamics

Vibration System & Instrumentation

- Installation & Maintenance

- System Upgrades (Machinery Diagnostic Platforms)

- Calibration & Linearity Checks

- Commissioning & Acceptance Testing

Performance Testing & Energy Audit

- Thermodynamic modelling

- Thermo-economic modelling

- Shop acceptance testing

- Power Monitoring & analysis

- Motor Current Signature Analysis

- Power & Fuel Optimization

Cooling Tower Testing

- CTI STD – 163 Vibration testing

- CTI ATC – Drift Testing

- CTI ATC – 105 Thermal Testing

- CTI ATC - 128 Sound Testing

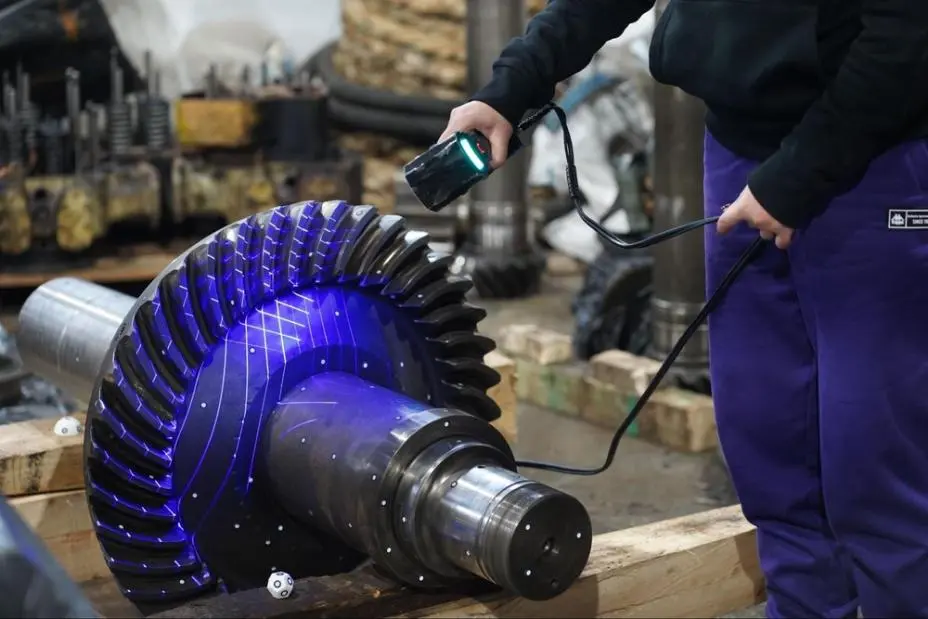

3D Scan & Laser Alignment

- 3D Scanning for upgrades and as built drawings

- STEAM TURBINE ALIGNMENT

- GAS TURBINE ALIGNMENT

- MACHINE TRAIN ALIGNMENT

- SHAFT LASER ALIGNMENT

- FOUNDATION LASER ALIGNMENT

- BORE LASER ALIGNMENT

Remote Diagnostic Support

- Configuration of Vibration Monitoring Systems

- Remote Data Collection, Analysis & Reporting

- Diagnostic Support with Recommendations

Support Service Agreements (SSAs)

Tailored to each client’s needs:

- Full Condition Monitoring Packages

- Integration with Reliability & Maintenance Programs

- Routine Machinery assessment surveys